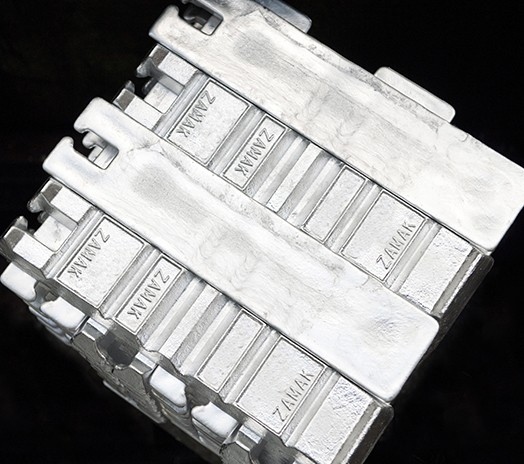

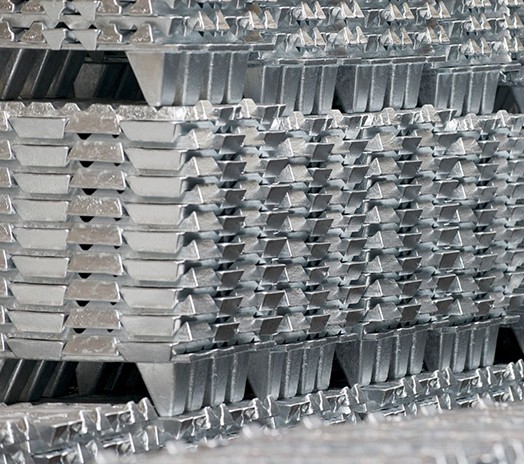

ZL-7 / Zamak 7

Zamak 7

Zamak 7 has less magnesium than zamak 3 to increase fluidity and ductility, which is especially useful when casting thin wall components.

Zamak 7 proved casting fluidity, ductility and surface finish.

Higher fluidity is sometimes desirable especially on components with intricate detail, however it does present special casting considerations

Zamak 7 is mostly used for special hardware applications, or when castings require extra formability during subsequent assembly operations such as crimping or staking. Its higher fluidity also allows thinner walls to be cast

Zamak 7 Chemical Analysis

| Analysis ( %) | Zamak 7 / ZL-7 |

|---|---|

| Al | 3.9 – 4.3 |

| Cu | ≤ 0.1 |

| Mg | 0.01 – 0.02 |

| Pb | ≤0.003 |

| Fe | ≤0.075 |

| Cd | ≤0.002 |

| Sn | ≤0.001 |

| Si | ≤0.001 |

| Ni | ≤0.001 |

Zamak 7 General Mechanical Properties

| Mechanical Properties | Metric Value |

|---|---|

| Ultimate Tensile Strength | 285 MPa |

| Yield Strength (0.2% offset) | 285 MPa |

| Impact Strength | 58.0 J |

| Elongation | 14% |

| Shear Strength | 214 MPa |

| Compressive Yield Strength | 414 MPa |

| Fatigue Strength (reverse bending 5×108cycles) | 47.0 MPa |

| Hardness | 80 Brinell |

Zamak 7 General Physical Properties

| Physical Properties | Metric Value |

|---|---|

| Solidification Range (melting range) | 381—387 °C |

| Density | 6.6 g/cm3 |

| Coefficient of Thermal Expansion | 27.4 μm/m-°C |

| Thermal Conductivity | 113 W/m-K |

| Electrical Resistivity | 6.4 μΩ-cm |

| Specific Heat Capacity | 419 J/kg-°C |